Bernd-Arno Behrens, Johanna Uhe, Hendrik Wester, Tim Matthias, Chistoph Büdenbender (2020); Procedia Manufacturing, Volume: 47, Pages: 309-314

Continuously increasing component requirements in terms of weight, strength, temperature resistance, but also costs and resource efficiency can no longer be fully met by monomaterials. The combination of different materials enables the ideal utilization of various material properties. Combinations of metal and plastic as well as, for example, steel and aluminium are possible. These combinations aim at reducing the overall weight of the component. The economic production of such hybrid components poses great challenges for modern manufacturing processes. Efficient process design is made possible by numerical process simulation. However, in addition to the properties of the materials used, this also requires information on the joining zone of the hybrid components under process-relevant conditions. Therefore, new test methods have been developed and tested in various research projects at the IFUM in recent years

Publication

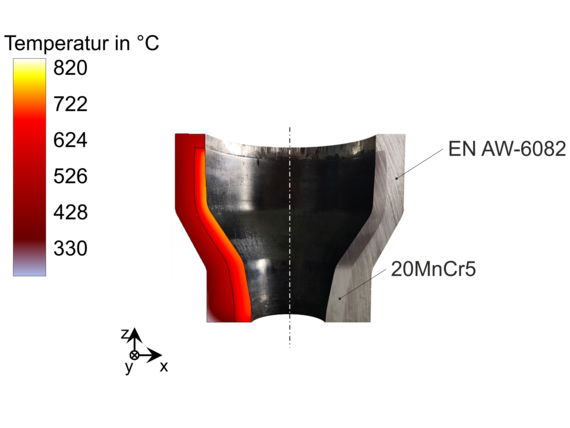

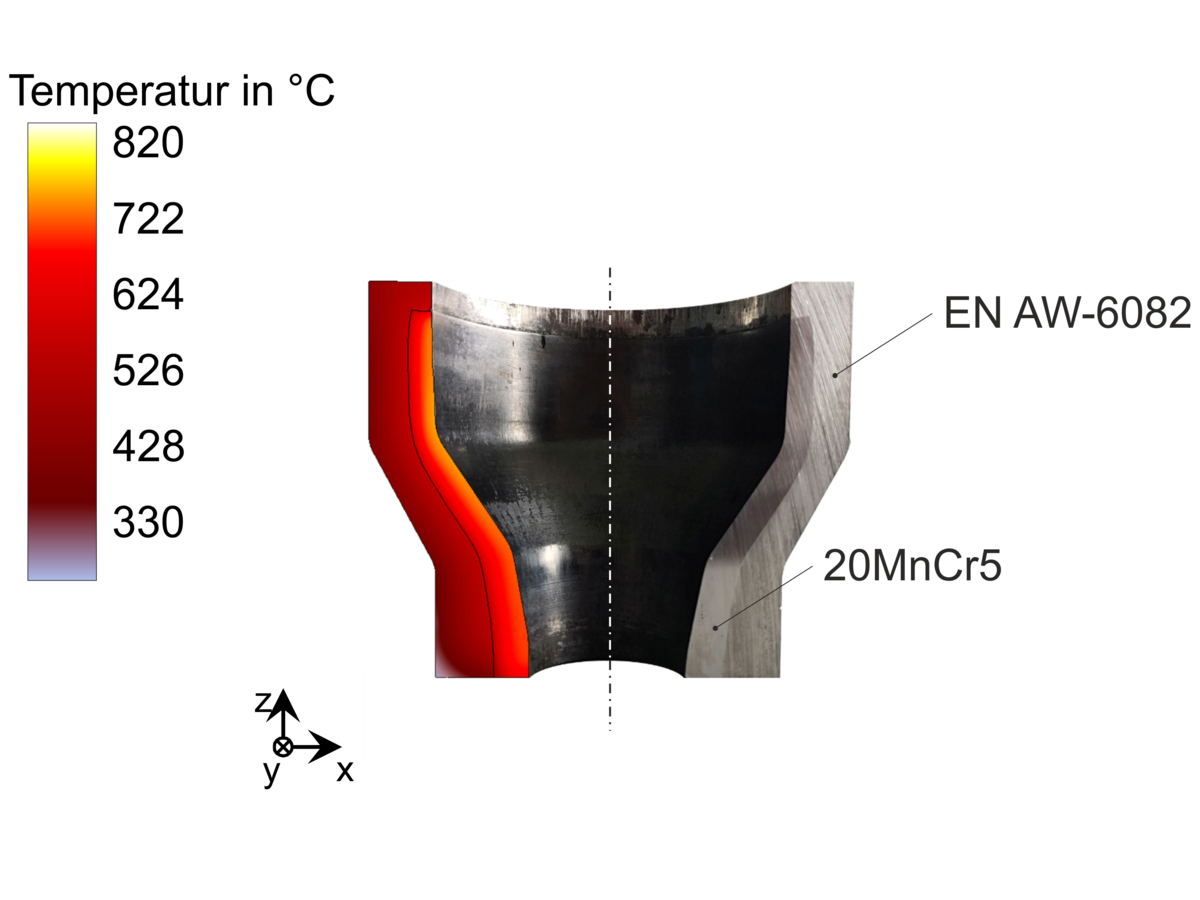

The investigation of a new process route for the production of hybrid components is the research focus of the Collaborative Research Centre SFB-1153 "Tailored Forming". Here, pre-assembled hybrid semi-finished products are used in various forging processes to produce locally adapted components. Using the example of a hybrid bearing bushing, the hybrid semi-finished product is produced by extrusion. In this process, a steel tube is pressed and coated with aluminium. This is followed by a forging operation. For stable process conditions, the initial temperature distribution inside the hybrid semi-finished product is essential.

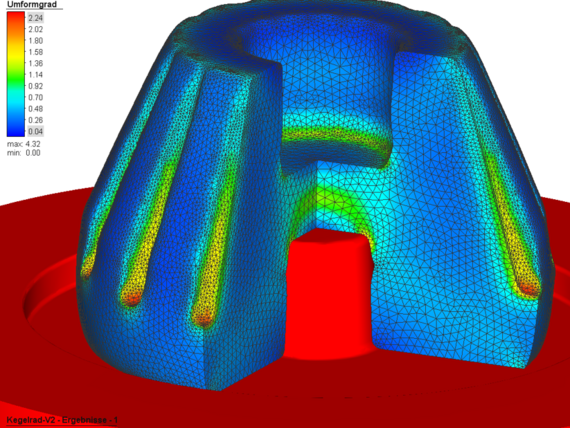

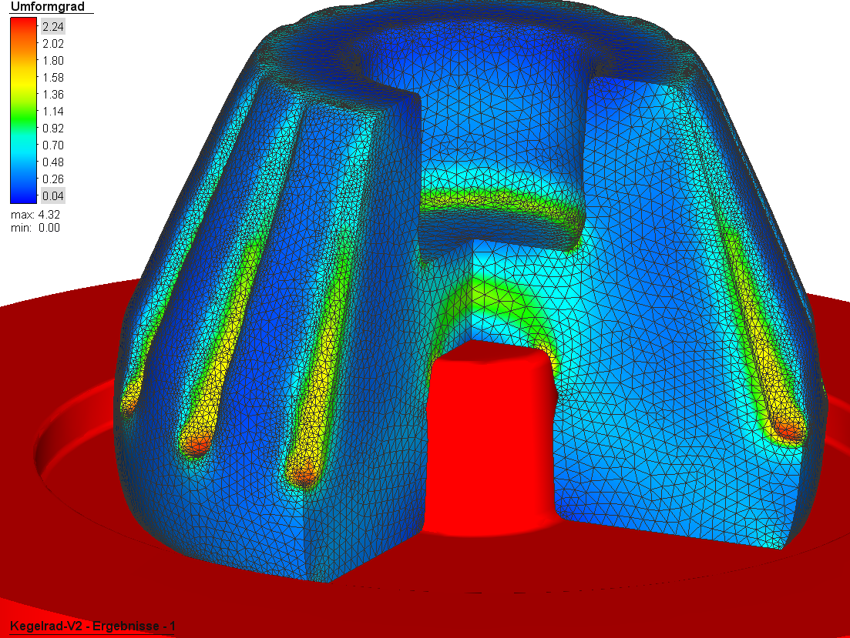

Another application example of hybrid components is a hybrid steel-steel bevel gear. The hybrid semi-finished product is produced by build-up welding. A wear-resistant steel layer is applied to a ductile steel core. Through a subsequent forming process, a customised bevel gear can be produced. An optimal initial layer thickness is determined by numerical simulation. In this way, customised components can be produced while at the same time optimising the use of materials.