Characterisation and modelling of medium Mn steel for the numerical simulation of hot sheet metal forming processes

| E-Mail: | fem@ifum.uni-hannover.de |

| Year: | 2024 |

| Funding: | Deutsche Forschungsgemeinschaft (DFG) - Projektnummer 505217238 |

| Duration: | 27 Monate |

The importance of components made of ultra-high-strength materials has increased in the recent years, especially in the automotive industry. This is due to the growing demand on weight reduction of car body components while keeping the same stiffness and simultaneously increasing the crash safety. The overall aim is to reduce the CO2 emissions of automobiles. Lightweight construction is also crucial for electric vehicles to increase the battery range. Compared to conventional cars, the additional battery weight must be compensated in order to maintain good driving characteristics. In this context, hot forming processes such as press hardening have become established for the production of structural parts of the car body.

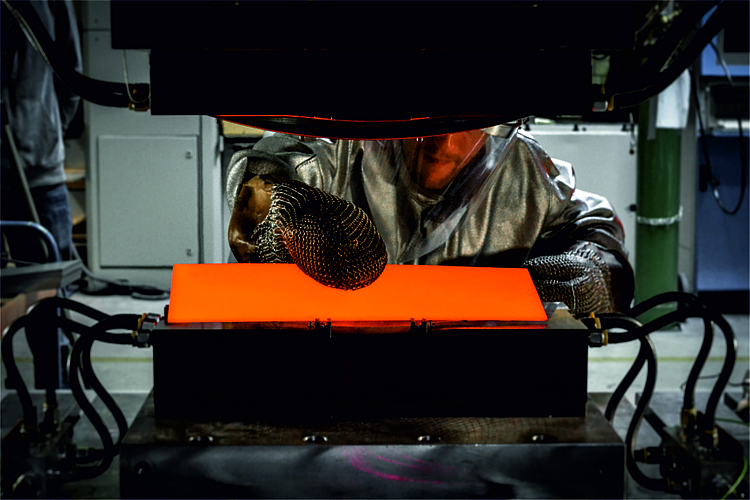

Since the experience with the hot press forming and the numerical simulation of medium Mn steel are currently limited, the aim of this project is to determine a process chain for the production of car body components made from a medium Mn steel. A detailed analysis regarding the hot press forming of medium Mn steel using FE simulation is planned, taking the formability at elevated temperatures, the structural transformations and their effects on the resulting component properties into account. This allows an evaluation to what extent medium Mn steel is suitable for hot press forming and replacing 22MnB5. Compared to press hardening of manganese-boron steels, hot press forming of medium Mn steel has various advantages in the field of sheet metal forming regarding the process side as well as the component side, such as a lower critical cooling rate and a higher adjustable elongation at break with simultaneously high strengths. A further advantage is the more resource-efficient production using medium Mn steel instead of 22MnB5 due to intercritical heating.