Transparent AI-supported process modeling in drop forging

| E-Mail: | massivumformung@ifum.uni-hannover.de |

| Year: | 2022 |

| Funding: | Deutsche Forschungsgemeinschaft (DFG) – SPP2422 |

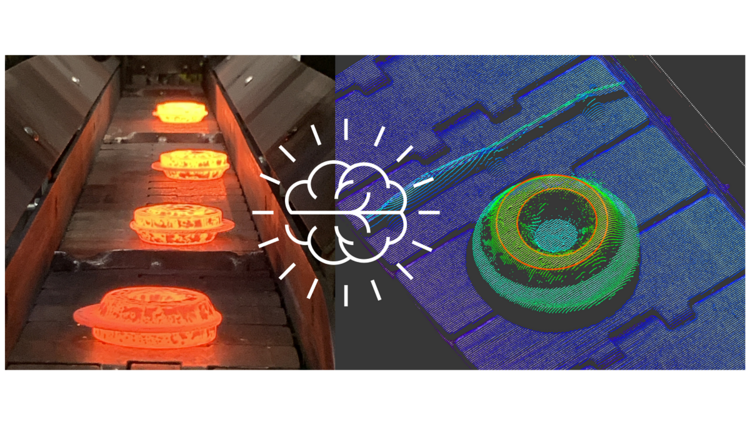

Serial forging processes are marked by significant fluctuations and complex interactions among various process parameters. Fully understanding these dynamic correlations remains challenging. The research project addresses this problem by generating high-quality datasets in a two-stage, automated drop forging process. The automation aims to enhance the consistency of the process flows, thereby enabling precise data collection.

A key component of data collection includes extensive temperature and force measurements, as well as image capture to identify specific quality characteristics of the components. These visual data are critical for understanding and optimizing forging results. The project incorporates transfer systems from automation technology to facilitate efficient tool changes and systematically sort finished components into a storage system. This orderly sorting is vital for traceability, as it allows a direct comparison of process parameters with individual components.

The development of an AI-based data model is at the forefront of the project. This model, trained with the collected data, is designed to recognize patterns and relationships too complex for human analysis. The goal is to use the AI system to predict quality characteristics in relation to process parameters, particularly concerning the optimal preform geometry. The insights gained aim to enhance the efficiency and quality of the forging process. The data collected in the project and the identified correlations between various influencing factors are compiled in a matrix. This matrix serves not only for the initial validation of the AI model but is also continually updated with new data to constantly refine the system's precision and reliability.