Production of areas with reduced strength in press-hardened components by means of a tempering station

| Year: | 2018 |

| Date: | 30-06-19 |

| Funding: | DFG |

| Duration: | 01/07/2017 – 30/06/2019 |

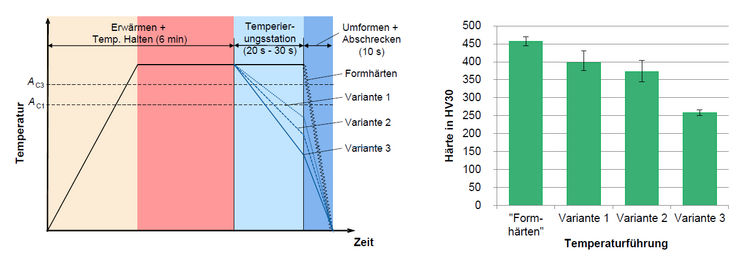

The transfer project should adapt the methodology of a local temperature control of austenitized materials before or between individual forming steps for the specific setting of a desired microstructure in a practical application using the example of press hardening. Graded material properties are obtained in the press-hardened components based on locally adapted microstructures by employing the technology of a two-phase spray cooling process in collaboration with the project partner, Volkswagen AG. Press-hardened components that have regions with locally reduced strength show an increased ability to join and facilitate trimming. In the proposed transfer project, the microstructural adjustment should take place through a targeted pre-cooling on localized component areas before the actual press hardening process. A suitable heat control unit must be developed to design such a pre-cooling by means of two-phase spray and simultaneous temperature control of component regions, which should not cool down and must be kept at a temperature above Ac3. For this purpose, numerical simulation models and experiences from the ongoing project can be used. In the pre-cooled areas first a temperature in the range of bainite or pearlite transformation should be adjusted to achieve a bainitic microstructural transformation during the subsequent and uniform cooling in the press-hardening tool. Areas quenched from a temperature level above Ac3 undergo a martensitic transformation due to cooling in the press-hardening tool. As an example, possible difference in hardness due to different temperature control is shown in Fig. 1. The advantage of this procedure is that no locally tempered press-hardening tools are required and short holding times during hot stamping can be used. Ultimately, it should be verified whether the tempering station is practically useful for the local formation of different microstructures by means of local cooling and maintaining the local austenitized state of the sheets at the same time. At Leibniz Universität Hannover, the design of the tempering station and the hot stamping is carried out at the Institute of Forming Technology and Machines, and the development of the pre-cooling device and the microstructure characterization is carried out at the Institut für Werkstoffkunde (Materials Science).