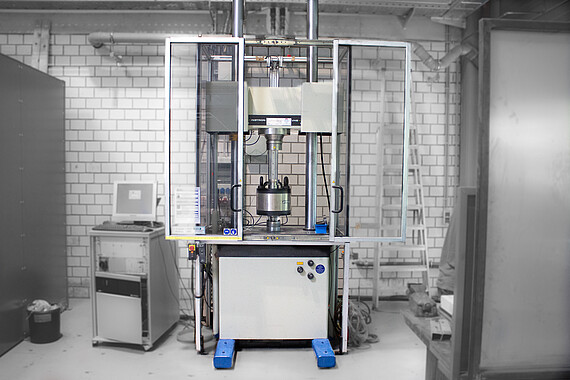

Servo-hydraulic forming simulator DYNSJ5590 / Plastometer

The servo-hydraulic forming simulator (plastometer) is a versatile material testing machine. Due to its open design, it is possible to realise and individually adapt a variety of test set-ups. Essentially, the machine can be operated in two modes. In closed loop mode, highly accurate flow curves (compressive stress) can be recorded together with the strain gauge load cell. In another tool system, together with an optical strain measurement system (GOM ARAMIS), forming limit curves can be determined both at room temperature and isothermally at up to 1000 °C.

In the open loop mode, cylinder crush tests can be carried out at high forming speeds using a special tool and adapted measuring software. The forming is carried out isothermally inside heat containers, which can also be tempered. The temperature range extends from room temperature to 1250 °C. The samples are heated in a chamber furnace. The forming speed can be kept constant throughout the test. Depending on the sample size, forming speeds of 1s-1 up to 100 s-1 are possible.

In addition, multiple forming or pulsed tests are also possible. The recrystallisation behaviour, for example, can be shown via a series of double crush tests and subsequently metallographically analysed.

| Parameter | Bereich |

|---|---|

| Manufacturer | Instron GmbH |

| Testing force | 300 kN |

| Punch speed | 100 mm/s (closed loop) / 2 m/s (open loop) |

| Recording | Piezoelectronic force transducer, high-speed displacement and acceleration sensors |

| Load cell | Strain gauge based load cell up to 500 kN |