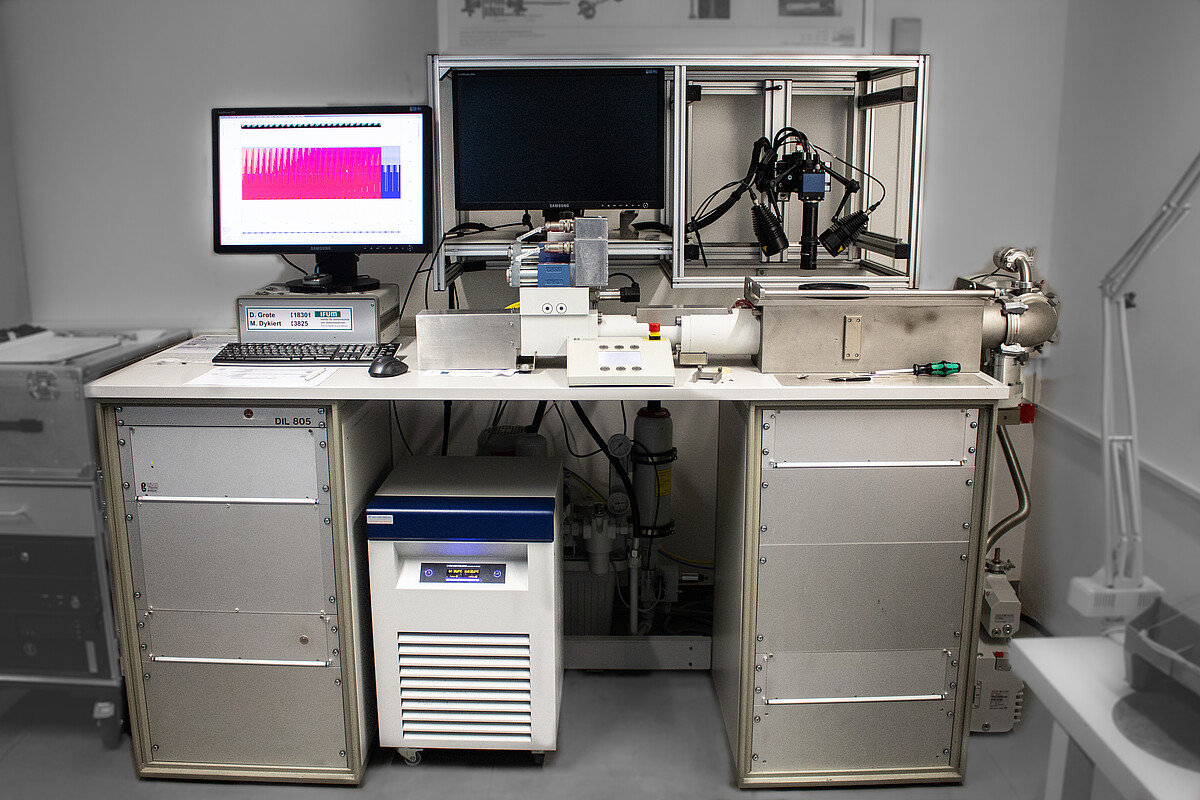

Quenching and deformation dilatometer DIL 805A/D+T

The quenching and deformation dilatometer DIL 805A/D+T enables the temperature-controlled measurement of thermal and mechanical length changes and thus the investigation of phase transformations as a function of time, temperature and mechanical stress.

The inductive heating and targeted cooling enables industrial heating and heat treatment processes to be simulated.

By adding the tensile-compressive and compressive modules, specimens can be subjected to defined tensile or compressive stresses. This allows the influence of a deformation on the microstructure to be investigated and flow curves to be recorded in tensile or crush tests.

Feasible experiments and experimental parameters:

Areas of application in quenching mode:

- Determination of the linear thermal expansion coefficient

- Determination of structural transformations

- Generation of time-temperature-transformation and time-temperature-austenitisation diagrams

The addition of the tension and compression insert modules allows tensile, compression and tension-compression tests to be carried out.

Areas of application in the Tension and Compression modes

- Recording of temperature-dependent flow curves

- Recording of structure-dependent flow curves

- Generation of D-CCT Diagrams

Optical strain measurement

- Extension through the self-sufficient, permanently installed ARAMIS 2D 4M system from the company GOM

- Image resolution of 2,400 x 1,728 pixels with a frame rate of up to 168 Hz

- Measuring lens with a focal length of 75 mm

- Enables the recording of local strains and the determination of anisotropy parameters

Technical data:

| Parameter | Range |

|---|---|

| Temperature range | 20 °C – 1.500 °C |

| Expansion range | 0,001 – 1 1/s |

| Heating method | induktiv |

| Atmosphere | inert gas (He, N), air, vacuum |

| Measurement resolution | 0,05 µm / 0,05 °C |

| Temperature measurement | up to three thermocouples per sample |

| Parameter | Range |

|---|---|

| Heating speed | max. 4.000 K/s |

| Cooling speed | max. 2.500 K/s |

| Parameter | Range |

|---|---|

| Heating speed | max. 100 K/s |

| Cooling speed | max. 100 K/s |

| Press force | max. 20 kN |

| Strain rate | 0,001 – 10 1/s |

| Thermocouples | Up to three per sample |

| Number of forming steps | arbitrary |

| Parameter | Range |

|---|---|

| Heating speed | max. 100 K/s |

| Cooling speed | max. 100 K/s |

| Press force | max. 10 kN |

| Forming speed | 0,001 – 1,0 1/s |

| Number of forming steps | arbitrary |