Selective thermally oxidated tool surfaces for dry deep drawing

| Year: | 2018 |

| Date: | 01-01-20 |

| Funding: | DFG |

| Duration: | 01.01.2014 – 01.01.2020 |

Friction and wear have significant influence on tool life in sheet metal forming. In this regard, lubricants are generally used to extend the tool life. Since the use of these lubricants does not correspond with the target of sustainable production, methods for dry forming are investigated in the priority program 1676.

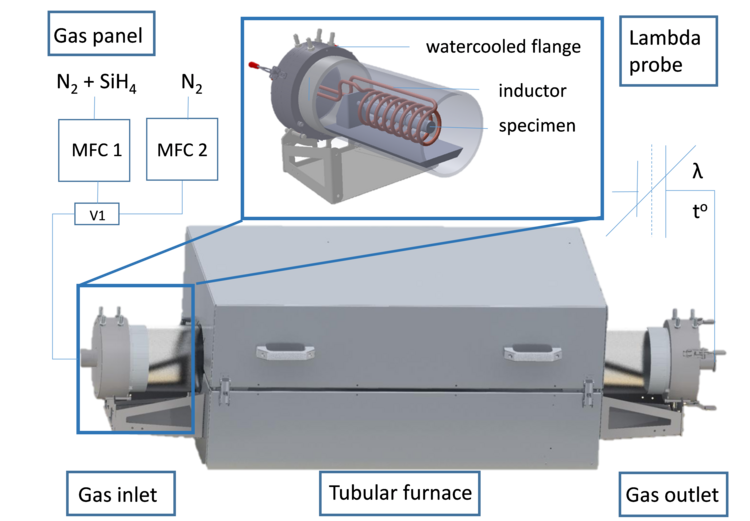

Within the scope of this project, the production and the use of tool coatings, which are produced by selective thermal oxidation, are investigated. The oxidative heat treatments of the tool surfaces take place at a defined oxygen residual. Therefore the treatments are carried out under a protective gas atmosphere (nitrogen) and monosilane doped nitrogen, respectively. So it is possible to generate oxide coatings with a defined chemical composition and thickness.

The investigation results from the first project period show that oxide layers produced under certain process conditions have friction coefficients, that are comparable to those measured on the tool surfaces after applying lubricants.

In the second phase of this subproject, an innovative heat treatment method has been developed. Conventionally, a continuance heating process was used to create the oxide layers. This manufacturing method requires an increased processing time and an increased amount of process gases. In comparison, the new heat treatment method deploys a tube furnace, which allows the production of oxidised-coated specimens with reduced protective gas consumption. In addition, an inductive heating unit was installed in the heating system to decrease process time d. Moreover, various surface modifications were investigated in the second phase of the project including friction and wear experiments. These, and further results from the numerical investigations carried out in the first and second project phases are necessary to understand the approach of dry metal forming researched and thus to ensure the industrial application of this forming technology. This point, applying the gathered experience in dry metal forming in industrial processeswill be the core of the research project in its third phase, whereby a modular deep-drawing tool is going tobe built, which will be equipped with oxidised mold inserts. By manufacturing different components with various geometries using the planned tool system it is possible to increase the load collective on the generated oxide layers successively and thus investigating the behaviour of the layer system in a conventional deep-drawing process. At the same time, the heat treatment process to produce the oxide layers will be continually optimised. Furthermore, the developed numerical model, which was validated on test specimens, will be deployed on the geometries investigated in this phase as well. Finally, the recreating process of the layer system will be investigated, so that more information about the tool life can be determined.