Bernd-Arno Behrens, Jörg Schröder, Dominik Brands, Lisa Scheunemann, Rainer Nierkamp, Alexander Chugreev, Mohammad Sarhil, Sonja Uebing, Christoph Kock (2019); Metals, Volume: 9, Issue: 4, Item number: 480

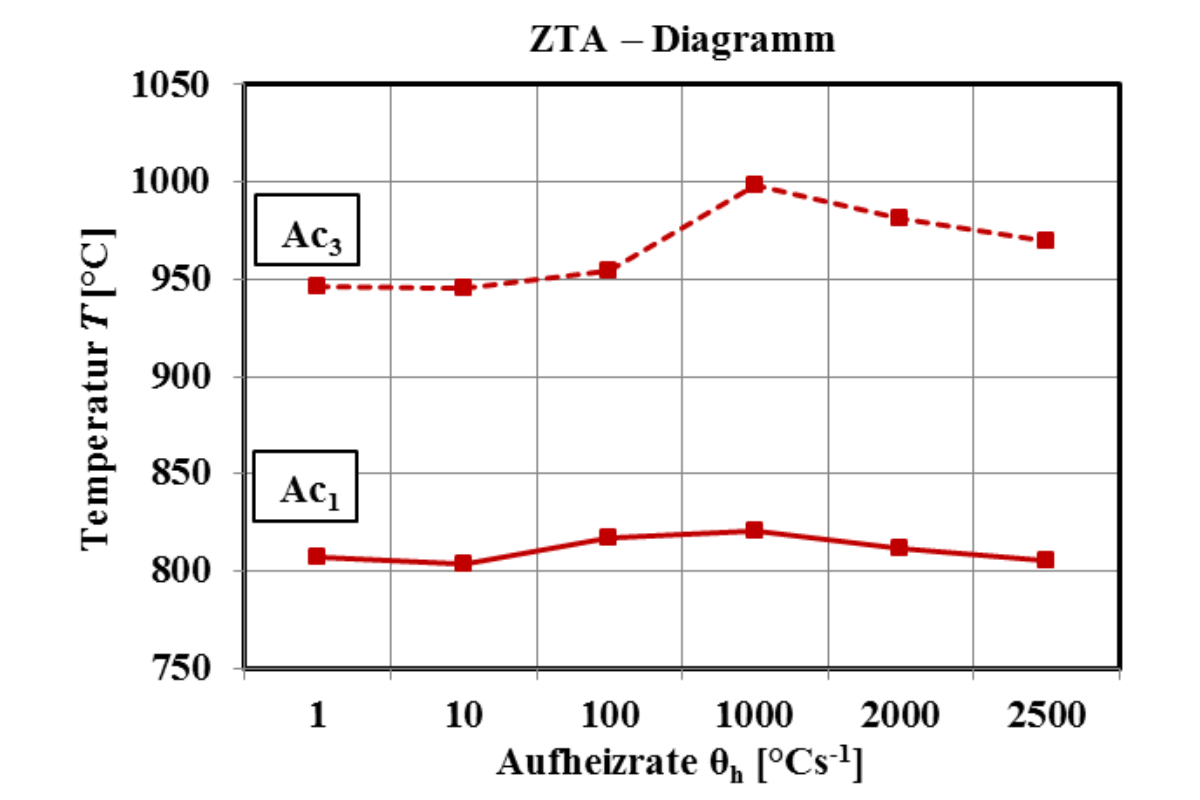

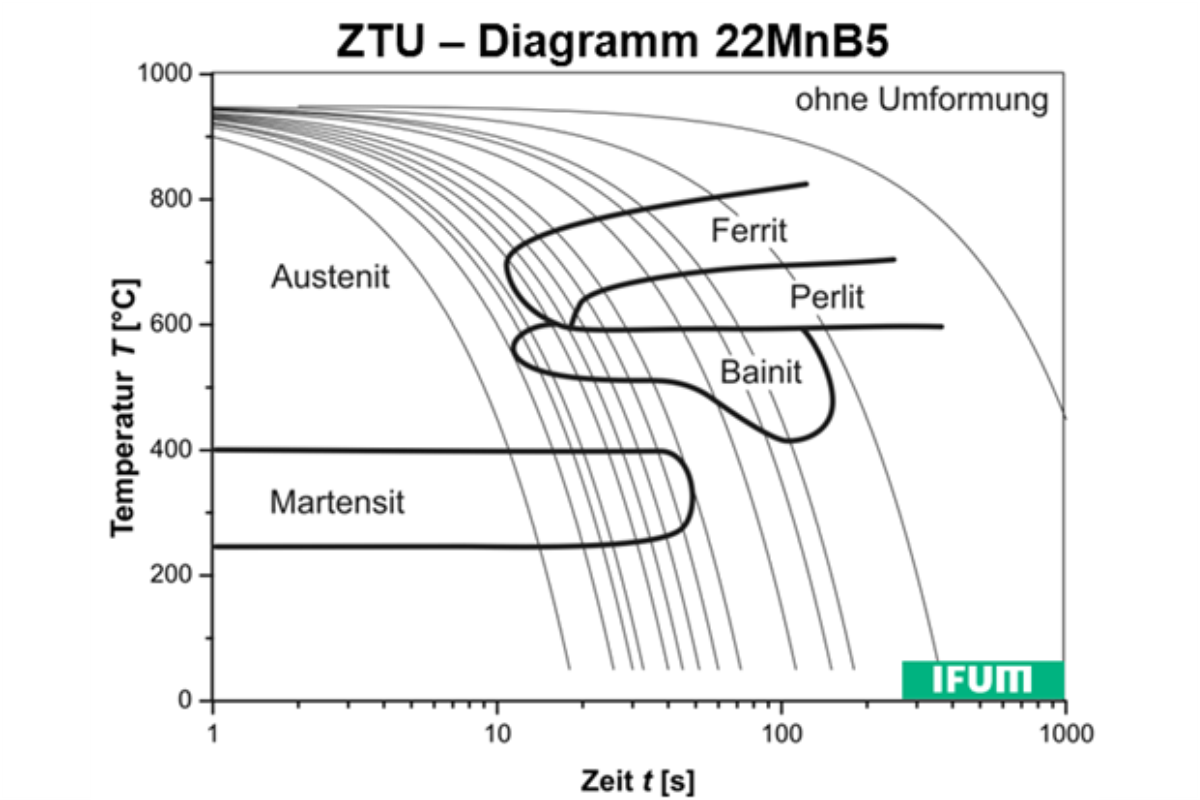

Modern age heat treatment has been a major factor in materials development over the last century. With its help, the mechanical properties of steels have been continuously improved and can now be specifically adjusted. In most cases, the phase transformations of steel in the solid state and the effect of a large number of alloying elements are utilised. The microstructural transformation behaviour of steel materials can be determined on the basis of dilatometric measurements in heating or cooling tests. Time-temperature austenitisation diagrams (CCT) and time-temperature transformation diagrams (TTT/CCT) can be used to illustrate the material behaviour during heating and cooling. In addition, hot working of the austenitised material affects the microstructural transformation behaviour, which is why, in addition to CCT diagrams, forming-TTA (forming TTT) diagrams are also used. Each of the diagram types mentioned has a strict validity only for the given material and must therefore be determined for this material. The quenching and forming dilatometer DIL 805A/D+T and the forming simulator Gleeble 3800-GTC are available at IFUM for such comprehensive microstructural transformation analysis. The resulting microstructure can also be analysed in detail in metallographic examinations.

Publication

The process of press hardening is gaining importance in view of the increasing demand for weight reduction combined with higher crash safety in cars. An alternative to the established manganese-boron steel 22MnB5 is hot-formed martensitic chromium steels such as AISI 420C. Strengths of 1850 MPa and elongations of 12 % are possible, exceeding those of 22MnB5. In industrial manufacturing, FE-simulation is commonly used in order to design car body parts cost-efficiently. Therefore, the characterization and the modelling of AISI 420C regarding flow stress, phase transformations as well as failure behaviour are presented in this paper. Temperature-depended flow curves are determined, showing the low flow stress and hardening behaviour at temperatures around 1000 °C. Cooling experiments are carried out, and a continuous cooling diagram is generated. Observed phases are martensite and retained austenite for industrial relevant cooling rates above 10 K/s. In addition, tests to investigate temperature-dependent forming limit curves are performed. As expected, the highest forming limit is reached at 1050 °C and decreases with falling temperature. Finally, a simulation model of a press-hardening process chain is set up based on the material behaviour characterised earlier and compared to experimental values. The forming force, phase transformation and forming limit could be calculated with good agreement to the experiment.