Bernd-Arno Behrens und Jonathan Ursinus (2020); Procedia Manufacturing, Volume 47, Seiten 329-334

At the IFUM, various powder metallurgical processes are investigated for the production of components, tools or specimens. In addition to conventional die pressing and sintering of steel and aluminium powders, the processing of powders by sinter forging or in FAST processes is also the focus of the investigations.

Publication

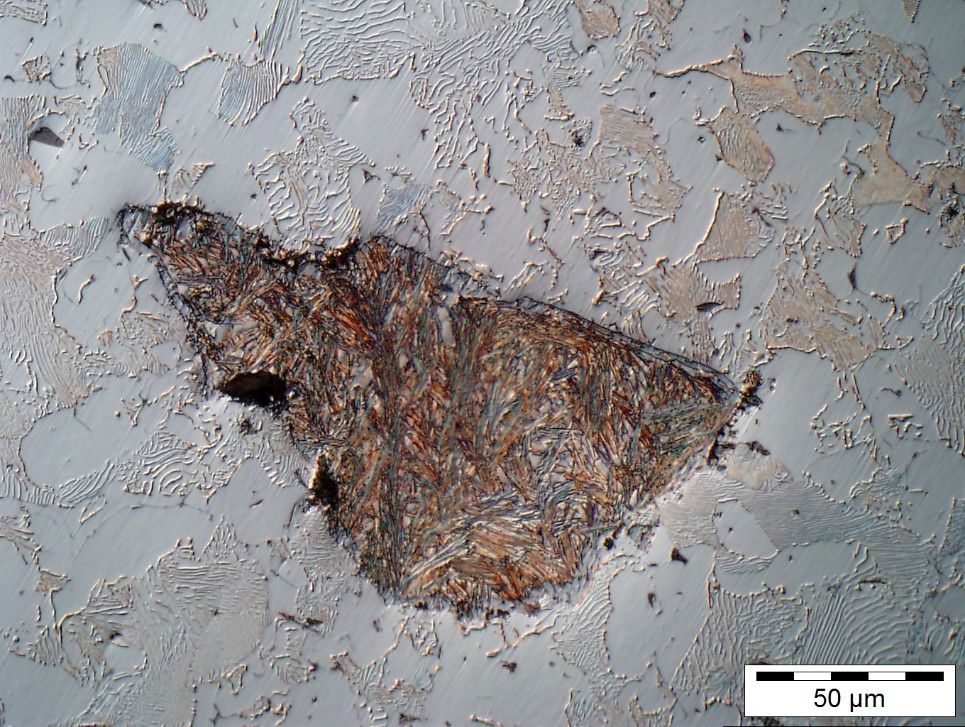

Hard composite materials combine a metal matrix with hard ceramic particles. This allows the properties of both materials to be exploited in a targeted manner. In this study, a hot work tool steel X40CrMoV5-1 was combined with tungsten fused carbide particles to increase the wear resistance of forming tools. A sinter-forging process was used to produce the material, and initial forging tests with the reinforced tools showed significant improvements over the conventional, unreinforced material.