H. Paschke, A. Nienhaus, K. Brunotte, T. Petersen, M. Siegmund, L. Lippold, M. Weber, M. Mejauschek, P. Landgraf, G. Braeuer, B.-A. Behrens, T. Lampke (2018); Adapted diffusion processes for effective forging dies, Volume 1960, Ausgabe 1

In the hot forming of serial products, tool wear plays a decisive role in the economic and ecological balance of the processes. For this reason, this area has long been the subject of intensive research at IFUM. Tool materials are being further developed and enhanced with coating systems or surface modifications. The effects are investigated at the institute in near-industrial forming tests using a fully automated forging cell. In model tests, wear mechanisms are isolated or investigated as a whole collective on the tools with the aid of measurement technology.

Publication

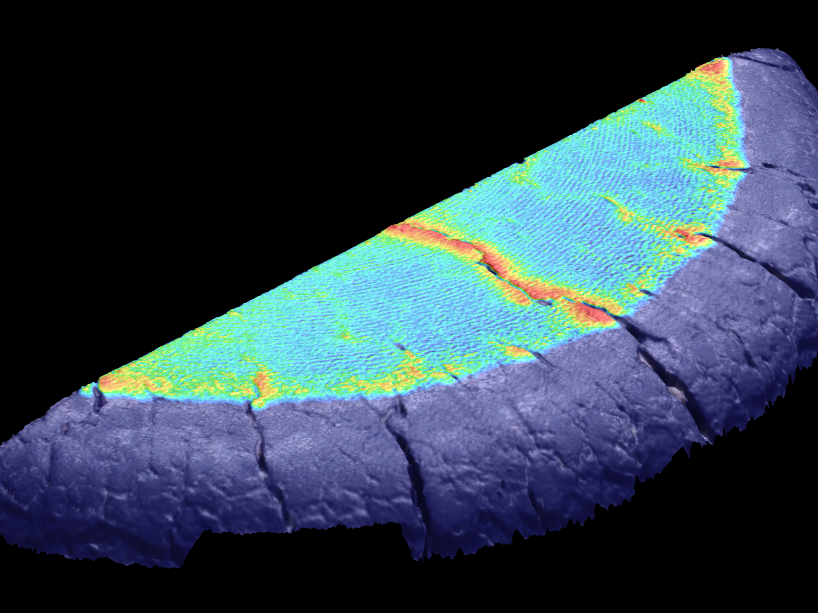

Tool wear due to plastic deformation or abrasion is accelerated by thermal softening of the die material. Nitriding processes are used to counteract this softening. However, while hot hardness is thus increased, these carry the risk of increased crack sensitivity due to the more brittle surface. This publication describes the selective structuring into nitrided and more ductile non-nitrided regions by suitable masking during the nitriding process. The tools modified in this way were tested in laboratory trials, production forging trials and industrial use.